The Internet of Things (IoT) is a rapidly growing network of interconnected devices that collect and exchange data through embedded software, electronics, and sensors. This vast network of physical objects offers numerous opportunities for direct integration of the physical world into computer-based systems, leading to improved automation, accuracy, and economic benefits across various industries.

IoT’s Potential Impact and Challenges

According to a McKinsey report, IoT products and services are projected to create between $5.5 trillion and $12.6 trillion in value by 2023. Factories and human health are expected to account for 36% to 40% of this unlocked value. However, realizing IoT’s full potential requires overcoming complexities such as developing sensing devices with secure cloud connectivity and generating valuable insights for end-users. Additionally, the ongoing semiconductor shortage and supply-chain disruptions caused by the COVID-19 pandemic continue to impact suppliers and manufacturers.

Advancements in IoT Technologies

Innovations in the four enabling technologies of IoT—chips, connectivity, security, and artificial intelligence (AI)—are driving down costs and leading to better devices. Improved networks result in more reliable connectivity, opening opportunities for previously infeasible applications. As interconnected devices demonstrate their value, demand booms across diverse businesses.

IoT in Action: Mobile World Congress 2023

The Mobile World Congress (MWC) 2023 highlighted the overwhelming emphasis on IoT. Major industry players announced partnerships and unveiled new products to support IoT growth. For example, HPE acquired Athonet, a seller of private core networks, while BICS announced a collaboration with Microsoft to help IoT devices switch seamlessly between private and public networks. Cisco partnered with NTT Ltd to develop a joint solution for private 5G deployments, and Deutsche Telecom announced its collaboration with Intelsat and Skylo to build out its satellite IoT value proposition.

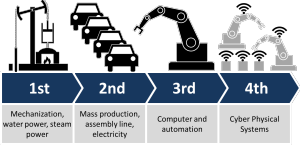

IoT and Industry 4.0: The Smart Factory Revolution

The manufacturing process has evolved dramatically over the last few decades. The Industrial Revolution introduced mechanized manufacturing processes, while the third industrial revolution brought computers into manufacturing. The fourth industrial revolution, Industry 4.0, aims to optimize computers by interconnecting them and giving them the ability to make manufacturing decisions independently. The “smart factory” is close to becoming a reality, thanks to physically connected systems, the Internet of Things, and the Internet of systems. Industry 4.0 has a positive impact on manufacturing processes, increasing speed and productivity. Predictive analytics can make it possible to predict problems before they happen based on patterns within the data.